Testing & quality detection

TESTING & QUALITY DETECTION

The PXID testing laboratory has obtained ISO 9001 quality system certification, enabling comprehensive and standardized testing of complete vehicles. The laboratory features a full-process testing area that strictly adheres to international quality standards for various assessments, including electric motors, batteries, electronic control systems, and the electrical safety and environmental testing of complete vehicles. Additionally, the laboratory conducts mechanical performance testing, range and energy consumption testing, as well as electromagnetic compatibility (EMC) testing, ensuring that every vehicle meets the highest industry standards for performance and safety, fulfilling stringent customer requirements.

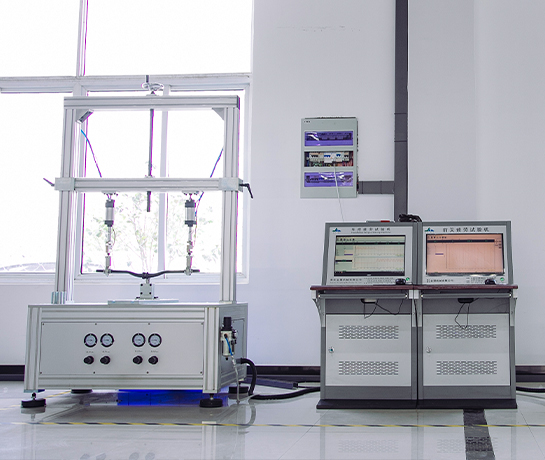

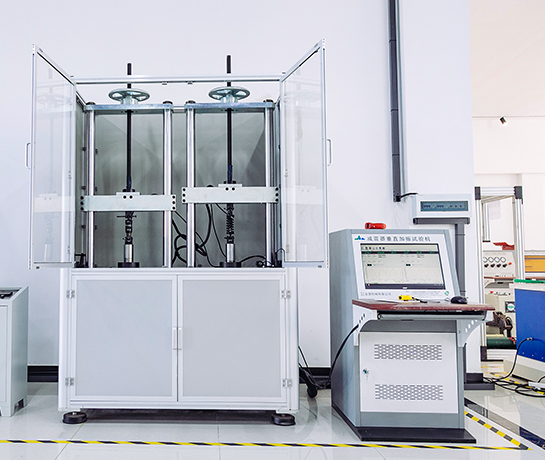

Full-Vehicle Durability Testing System

PXID conducts systematic full-vehicle durability tests to simulate long-term usage conditions, ensuring structural stability and safety under high-stress scenarios. Testing includes frame horizontal and vertical fatigue, drop impact, fork impact, and whole-vehicle vibration, supplemented by fork horizontal fatigue and suspension vertical excitation. These procedures guarantee long-term reliability for end users.

Motor performance testing

Ensure that the motor’s output power and efficiency meet design requirements and can operate stably. Conduct tests for power and efficiency, speed and torque, temperature rise, and noise to verify the motor’s performance, power output, and stability, ensuring it provides reliable power support in electric bicycles.

Battery system testing

Test the battery’s capacity, output voltage, and safety by performing capacity tests, charging and discharging tests, battery protection tests, and temperature and safety tests. This ensures the battery’s capacity, endurance, and safety performance meet standards, providing stable power for the motor and control system.

Control system testing

Conduct tests on controller functions, riding mode switching, speed sensors, torque sensors, and communication systems to ensure the control system can precisely manage the motor and battery, providing stable assistance under different riding conditions and enhancing the riding experience.

Range and power consumption Testing

Evaluate the electric bicycle’s endurance, ensuring the battery range meets design requirements. Conduct real-world riding tests under different assistance modes to assess the battery’s range after a single charge, ensuring it meets daily riding needs. Measure the motor’s energy consumption under various speeds and load conditions to evaluate battery usage, ensuring it aligns with design expectations.

Electromagnetic compatibility

(EMC) testing

Test whether the control system and motor can function normally under external electromagnetic interference, ensuring system resistance to disturbances. Assess the electromagnetic radiation generated during the operation of the electric bicycle to ensure it does not interfere with surrounding electronic devices (like phones and GPS).

Environmental Reliability Testing Laboratory

The environmental testing lab conducts high-temperature, low-temperature, thermal-cycling, humidity, and salt-spray testing to validate product reliability under extreme conditions. This systematic verification ensures consistent performance and safety across global environments.

Electrical System Safety Validation

Electrical safety validation includes insulation-resistance testing, waterproof testing, over-current and over-voltage protection testing, and short-circuit protection. These tests ensure system safety and compliance, preventing electrical hazards during real-world use.

Industrial design

Initial hand-drawn sketches

3D modeling and rendering

Material and manufacturing process selection

CMF design (Color, Material, Finish)

Customized UI experience design

International Awards: Recognized with Over 15 International Innovation Awards

PXID has received more than 15 distinguished international innovation awards, highlighting its exceptional design capabilities and creative achievements on the global stage. These accolades affirm PXID’s leadership in product innovation and design excellence.

Patent Certificates: Holder of Multiple Domestic and International Patents

PXID has secured numerous patents across various countries, showcasing its dedication to cutting-edge technology and intellectual property development. These patents reinforce PXID’s commitment to innovation and its ability to offer unique, proprietary solutions to the market.

Industrial design

Initial hand-drawn sketches

3D modeling and rendering

Material and manufacturing process selection

CMF design (Color, Material, Finish)

Customized UI experience design

International Awards: Recognized with Over 15 International Innovation Awards

PXID has received more than 15 distinguished international innovation awards, highlighting its exceptional design capabilities and creative achievements on the global stage. These accolades affirm PXID’s leadership in product innovation and design excellence.

Patent Certificates: Holder of Multiple Domestic and International Patents

PXID has secured numerous patents across various countries, showcasing its dedication to cutting-edge technology and intellectual property development. These patents reinforce PXID’s commitment to innovation and its ability to offer unique, proprietary solutions to the market.

Industrial design

Initial hand-drawn sketches

3D modeling and rendering

Material and manufacturing process selection

CMF design (Color, Material, Finish)

Customized UI experience design

International Awards: Recognized with Over 15 International Innovation Awards

PXID has received more than 15 distinguished international innovation awards, highlighting its exceptional design capabilities and creative achievements on the global stage. These accolades affirm PXID’s leadership in product innovation and design excellence.

Patent Certificates: Holder of Multiple Domestic and International Patents

PXID has secured numerous patents across various countries, showcasing its dedication to cutting-edge technology and intellectual property development. These patents reinforce PXID’s commitment to innovation and its ability to offer unique, proprietary solutions to the market.

Industrial design

Initial hand-drawn sketches

3D modeling and rendering

Material and manufacturing process selection

CMF design (Color, Material, Finish)

Customized UI experience design

International Awards: Recognized with Over 15 International Innovation Awards

PXID has received more than 15 distinguished international innovation awards, highlighting its exceptional design capabilities and creative achievements on the global stage. These accolades affirm PXID’s leadership in product innovation and design excellence.

Patent Certificates: Holder of Multiple Domestic and International Patents

PXID has secured numerous patents across various countries, showcasing its dedication to cutting-edge technology and intellectual property development. These patents reinforce PXID’s commitment to innovation and its ability to offer unique, proprietary solutions to the market.

Industrial design

Initial hand-drawn sketches

3D modeling and rendering

Material and manufacturing process selection

CMF design (Color, Material, Finish)

Customized UI experience design

International Awards: Recognized with Over 15 International Innovation Awards

PXID has received more than 15 distinguished international innovation awards, highlighting its exceptional design capabilities and creative achievements on the global stage. These accolades affirm PXID’s leadership in product innovation and design excellence.

Patent Certificates: Holder of Multiple Domestic and International Patents

PXID has secured numerous patents across various countries, showcasing its dedication to cutting-edge technology and intellectual property development. These patents reinforce PXID’s commitment to innovation and its ability to offer unique, proprietary solutions to the market.

Industrial design

Initial hand-drawn sketches

3D modeling and rendering

Material and manufacturing process selection

CMF design (Color, Material, Finish)

Customized UI experience design

International Awards: Recognized with Over 15 International Innovation Awards

PXID has received more than 15 distinguished international innovation awards, highlighting its exceptional design capabilities and creative achievements on the global stage. These accolades affirm PXID’s leadership in product innovation and design excellence.

Patent Certificates: Holder of Multiple Domestic and International Patents

PXID has secured numerous patents across various countries, showcasing its dedication to cutting-edge technology and intellectual property development. These patents reinforce PXID’s commitment to innovation and its ability to offer unique, proprietary solutions to the market.

Industrial design

Initial hand-drawn sketches

3D modeling and rendering

Material and manufacturing process selection

CMF design (Color, Material, Finish)

Customized UI experience design

International Awards: Recognized with Over 15 International Innovation Awards

PXID has received more than 15 distinguished international innovation awards, highlighting its exceptional design capabilities and creative achievements on the global stage. These accolades affirm PXID’s leadership in product innovation and design excellence.

Patent Certificates: Holder of Multiple Domestic and International Patents

PXID has secured numerous patents across various countries, showcasing its dedication to cutting-edge technology and intellectual property development. These patents reinforce PXID’s commitment to innovation and its ability to offer unique, proprietary solutions to the market.